Introduction

Finding a manufacturing method that balances cost with precision often feels like a losing battle. You might struggle with sand casting’s rough finishes requiring expensive machining, or perhaps you balk at the high upfront tooling costs of investment casting for a mid-volume run. It’s frustrating when a prototype fails simply because the surface finish wasn’t up to spec.

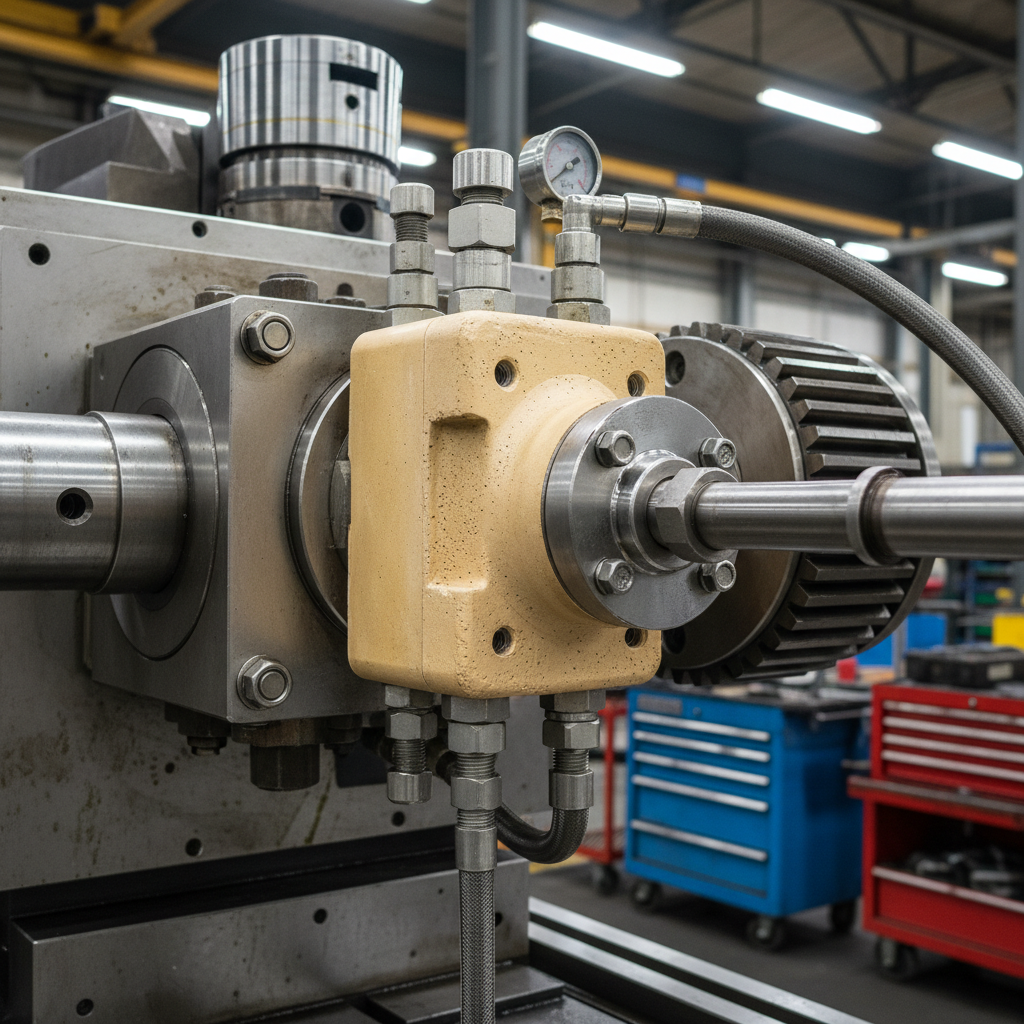

Plaster mold casting offers a sophisticated solution, delivering near-die-cast quality with significantly lower tooling investments. This process is the “missing link” for engineers needing parts that fit perfectly the first time without weeks of post-processing. Whether you are designing a complex decorative piece or testing a new hydraulic fitting design, understanding this technique can save your production timeline.

1. What Is Plaster Mold Casting and Why Is It Used?

Plaster mold casting is a specialized manufacturing process similar in concept to sand casting but uses a plaster of paris mixture instead of sand to form the mold. This distinct difference allows manufacturers to produce components with exceptionally smooth surfaces and tight tolerances, much like you would expect from a precision-machined hydraulic adapter used in critical aerospace applications. The plaster mixture, often fortified with talc or magnesium oxide, creates a mold with low thermal conductivity. This property forces the molten metal to cool slowly, ensuring that intricate details and thin walls are captured perfectly.

The Precision Advantage

Here is the deal: using plaster allows you to achieve geometries that would be impossible or too costly with other methods. The resulting parts often require little to no machining, which is a massive advantage when working with expensive alloys. Manufacturers turn to this method when they need the detail of investment casting but want to avoid the high cost of wax patterns and ceramic shells. It serves as a perfect bridge technology for medium production runs where quality cannot be compromised.

Key Features

- Precision: Achieves tolerances as tight as ±0.005 inches per inch.

- Finish: Produces a surface finish of 63-125 RMS standard.

- Complexity: Ideal for parts with undercuts, blind holes, and complex geometries.

Comparison Summary

| Feature | Plaster Casting | Sand Casting | |

|---|---|---|---|

| Mold Material | Gypsum Plaster | Silica Sand | |

| Surface Finish | Smooth (63 RMS) | Rough (300+ RMS) | |

| Cooling Rate | Slow | Fast | |

| Detail Level | High | Low/Medium |

Analysis: The primary value proposition of plaster casting lies in its ability to replicate fine details without the high initial tooling costs of die casting.

2. How Does the Plaster Casting Process Work Step-by-Step?

The journey from a digital design to a finished metal part involves several critical steps. It begins with creating a master pattern, usually made from metal or durable plastic, which determines the geometry of the final part. This pattern must include all necessary features, such as connection points found on a standard manufacturing component. The pattern is sprayed with a parting compound to prevent sticking. A slurry of gypsum plaster and water is then poured over the pattern and agitated to remove air bubbles, ensuring the mold captures every minute detail.

Managing Moisture

You might be wondering, how does the plaster withstand the heat without cracking? The secret lies in the baking process. Once the plaster sets, the mold is removed from the pattern and baked in an oven at high temperatures. This step is non-negotiable as it removes all moisture from the mold. Any remaining water would turn to steam instantly upon contact with molten metal, causing the mold to explode or creating severe porosity in the part.

Process Workflow

| Step | Action | Critical Factor | |

|---|---|---|---|

| 1. Pattern Prep | Coat pattern with release agent | Prevents sticking | |

| 2. Slurry Mix | Combine gypsum & water | Remove air bubbles | |

| 3. Setting | Allow plaster to harden (~15 mins) | Structural integrity | |

| 4. Baking | Heat to remove moisture (12-72 hrs) | Crucial for safety | |

| 5. Pouring | Inject molten metal | Gravity or low pressure |

Analysis: The extended baking cycle is the process bottleneck but is non-negotiable for safety and part integrity.

3. What Materials Are Best Suited for Plaster Casting?

Plaster casting is almost exclusively used for non-ferrous metals with lower melting points. The high heat of ferrous metals like steel would destroy the gypsum mold before the part solidifies—unlike a forged steel component which uses higher temperature processes. The most common alloys used are aluminum, magnesium, zinc, and copper-based alloys such as brass fittings and bronze.

Thermal Benefits

But here’s the kicker: the insulating properties of plaster actually help these specific materials flow better. Because the mold does not suck the heat out of the metal quickly, the alloy remains fluid, filling intricate details and thin walls (down to 0.040 inches) that would be impossible in a chill-prone sand mold. This makes it the go-to choice for complex aluminum housings and decorative brass hardware.

Material Compatibility

| Material | Melting Point | Suitability for Plaster | |

|---|---|---|---|

| Aluminum | ~1,220°F | Excellent | |

| Zinc | ~787°F | Excellent | |

| Brass | ~1,700°F | Good (Special Plaster Required) | |

| Steel | ~2,500°F | Not Suitable |

Analysis: While you cannot cast steel, the ability to cast complex aluminum and brass parts makes it indispensable for specific industries.

4. Why Choose Plaster Casting Over Sand Casting?

When surface finish and dimensional accuracy are paramount, plaster casting is the clear winner over sand casting, especially if you are manufacturing a component that requires a perfect seal. Sand casting leaves a granular texture that almost always requires extensive machining to smooth out. In contrast, plaster casting produces a “near-net-shape” part right out of the mold, preserving fine details like lettering, logos, and pre-cast threads.

Reducing Post-Processing

Let’s face it, nobody wants to pay for unnecessary machining hours. While the initial mold preparation for plaster takes longer and costs slightly more than a simple sand mold, the savings in post-processing are massive. You eliminate the need for grinding, polishing, and facing operations. For parts where aesthetics or flow dynamics are critical, the smooth surface of a plaster cast part provides immediate value without the extra labor.

Attribute Comparison

| Attribute | Plaster Mold | Sand Mold | |

|---|---|---|---|

| Surface Roughness | 1.6 – 3.2 µm Ra | 12.5 – 25 µm Ra | |

| Min. Wall Thickness | 1.0 mm | 3.0 mm | |

| Machining Required | Minimal | Extensive | |

| Cost per Mold | Moderate | Low |

Analysis: The cost savings in post-processing usually offset the higher initial molding cost of plaster compared to sand.

5. How Does Plaster Casting Benefit Prototype Development?

Plaster casting is a favorite among engineers for prototyping because it allows for the rapid creation of metal parts that function identically to production die-cast parts. This is essential when testing a new custom hydraulic fitting design under real-world pressure. Since the master pattern can be made of easy-to-machine materials or even 3D printed plastics, design changes can be implemented quickly without hard tooling.

Die-Cast Simulation

Here is the secret: you can simulate die-cast properties without the $50,000 tooling investment. If you need 50 to 100 prototype parts for a beta test, plaster casting provides the mechanical properties of a cast metal part, unlike 3D printed metal which can be porous. This validation stage is critical for avoiding costly mistakes before committing to mass production steel molds.

Development Benefits

| Prototyping Method | Tooling Cost | Lead Time | Material Properties | |

|---|---|---|---|---|

| Plaster Casting | Low | 1-2 Weeks | Production Grade | |

| Die Casting | Very High | 8-12 Weeks | Production Grade | |

| 3D Printing (Metal) | High | 3-5 Days | Variable/Porous |

Analysis: For validating mechanical properties before mass production, plaster casting provides the best cost-to-performance ratio.

6. What Are the Main Applications of Plaster Casting?

This method is widely used in industries requiring lightweight precision parts, from waveguides in telecommunications to specialized housings and even low-pressure components for fluid transfer systems. Its ability to form intricate internal passageways makes it particularly valuable for aerospace and defense sectors where weight reduction is critical and failure is not an option.

Critical Industries

Think about it: precision and weight reduction are non-negotiable when you are 30,000 feet in the air. Engineers rely on plaster casting to create thin-walled aluminum components that house sensitive electronics or direct air flow. In the medical field, the smooth finish allows for easy sterilization of device handles and equipment housings.

Application Spectrum

| Industry | Common Parts | Key Requirement | |

|---|---|---|---|

| Aerospace | Waveguides | Smooth internal finish | |

| Medical | Device Housings | Aesthetics/Sterilization | |

| Automotive | Prototyping | Die-cast simulation | |

| Electronics | Heat Sinks | Complex fin geometry |

Analysis: The versatility of plaster casting allows it to serve niche high-value sectors effectively.

7. What Limitations Should You Consider?

Despite its advantages, plaster casting is not a universal solution. For example, you cannot use it to mass-produce a high-pressure hydraulic adapter made of carbon steel due to the melting temperature limits of the plaster mold. Additionally, the process is generally slower than other casting methods because the plaster has low permeability. This means gases cannot escape easily through the mold wall, requiring longer cooling times.

Economic and Physical Limits

Wait, there’s more: the mold is expendable, meaning it must be destroyed to remove the part. Unlike a permanent die that spits out a part every few seconds, every single plaster cast part requires a new mold to be made from the master pattern. This limits the economic viability for high-volume production runs where millions of parts are needed annually.

Key Limitations

| Limitation | Impact | Alternative Process | |

|---|---|---|---|

| High Melting Point | Cannot cast steel | Investment Casting | |

| High Volume | Slow cycle time | Die Casting | |

| Large Scale | Mold fragility | Sand Casting |

Analysis: Plaster casting is a specialized tool, not a replacement for high-volume steel production methods.

8. How Does Surface Finish Compare to Other Methods?

The surface finish achieved with plaster casting is superior to almost all other gravity casting methods, ensuring that sealing surfaces on a manufacturing component require little to no machining. The fine grain of the plaster replicates the master pattern’s texture exactly, often resulting in a satin-smooth look immediately after breakout.

Aesthetic and Functional Quality

You’ll want to know this: excellent surface finish translates directly to better fatigue strength. A smoother surface has fewer micro-cracks and imperfections where stress fractures can begin. For parts carrying fluid, like a pump housing or a valve body, the smooth internal walls reduce turbulence and improve flow efficiency compared to the rough walls of a sand casting.

Surface Quality Data

| Process | Typical RMS | Appearance | |

|---|---|---|---|

| Plaster Casting | 63-125 | Smooth, Satin | |

| Investment Casting | 63-125 | Smooth | |

| Perm Mold | 200-300 | Good | |

| Sand Casting | 300-560 | Rough, Granular |

Analysis: For cosmetic parts or fluid-flow components, the superior finish reduces friction and improves aesthetics.

9. What Is the Cost Structure of Plaster Casting?

The cost structure of plaster casting is a hybrid: it has low tooling costs like sand casting but higher piece prices due to the longer cycle times and labor intensity. This makes it perfect for mid-volume runs. It avoids the massive upfront capital of die casting while delivering a part that looks and performs significantly better than a cheap sand casting.

Total Cost of Ownership

Here’s the bottom line: it saves money on low-to-medium volume production. If you need a specialized part but can’t justify a $50,000 mold, plaster casting is your answer. You must look at the Total Cost of Ownership (TCO) rather than just the raw casting price. Contact us for a detailed cost analysis for your specific project needs.

Cost Driver Breakdown

| Cost Driver | Plaster Casting | Die Casting | Sand Casting | |

|---|---|---|---|---|

| Initial Tooling | $$ | $$$$$ | $ | |

| Unit Price | $$$ | $ | $$ | |

| Machining Cost | $ | $ | $$$ | |

| Total (Low Vol) | Best Value | High | Medium |

Analysis: Do not look at the piece price in isolation; calculate the savings from eliminated machining operations.

10. How Do You Ensure Quality in Plaster Cast Components?

Quality assurance in plaster casting involves rigorous inspection of the master pattern and the final casting to ensure no defects exist that could compromise a critical connection. Because the process is used for precision parts, manufacturers often employ non-destructive testing methods to verify internal integrity and dimensional accuracy.

Verification Standards

Make no mistake, precision requires verification. At a professional facility, technicians monitor the plaster mixing ratio, the baking temperature, and the metal pouring rate. Post-casting, parts are checked with Coordinate Measuring Machines (CMM) to ensure they meet the tight ±0.005 tolerance. If a part is intended for a hydraulic application, it may also undergo pressure testing. For more on our rigorous standards, visit Topa Hydraulic Parts .

Quality Control Protocol

| Inspection Type | Purpose | Frequency | |

|---|---|---|---|

| CMM | Dimensional Accuracy | Random Sampling | |

| X-Ray | Internal Porosity | Critical Parts | |

| Dye Penetrant | Surface Cracks | 100% Visual | |

| Alloy Analysis | Material Grade | Per Batch |

Analysis: Consistent process control during the plaster mixing and baking phases is the root of quality.

Conclusion

Plaster mold casting remains an unrivaled method for producing high-precision, smooth-finished non-ferrous parts without the exorbitant tooling costs of die casting. Whether you are prototyping a complex hydraulic component or manufacturing intricate aerospace parts, this process offers the detail and accuracy your projects demand. By understanding the specific benefits and limitations of this technique, you can make smarter manufacturing decisions that save time and money.

If you are ready to explore how precision casting can elevate your next project, contact us today to speak with a manufacturing specialist.

FAQ

Q1. Can I use plaster casting for steel parts?No, because the melting point of steel (approx. 2,500°F) is too high for the gypsum plaster mold. The extreme heat causes the plaster to break down and release sulfur, which destroys the mold integrity and ruins the metal.

Q2. Is plaster casting cheaper than sand casting?No, typically plaster casting has a higher piece price than sand casting. This is due to the more involved mold preparation (baking time) and longer cooling periods. However, it often results in a lower total cost for the finished part because it significantly reduces or eliminates the need for expensive post-casting machining.

Q3. How accurate is plaster mold casting?Yes, it is extremely accurate. It can achieve tolerances of ±0.005 inches per inch, making it one of the most precise gravity casting methods available. This precision allows for “near-net-shape” manufacturing, where the cast part is very close to the final dimensions required.

Q4. Can I cast threads directly into the part?Yes, due to the high fidelity of the plaster mold, coarse external threads and some internal features can be cast directly. This is a major advantage over sand casting, as it reduces the need for secondary tapping or threading operations, saving time and production costs.

Q5. How long does it take to get a plaster cast part?Yes, it is relatively fast compared to hard tooling methods. Standard lead times for prototypes are often 1-2 weeks, whereas production tooling for die casting can take 8-12 weeks to manufacture. This speed makes it ideal for rapid prototyping and market testing.