Using incorrect hydraulic connectors often leads directly toward leaks, pressure drops, or complete system blowouts. A single failure creates costly downtime while posing serious safety risks for machine operators nearby. This guide provides every necessary criterion for selecting a perfect hydraulic fitting for any specific application you face. Backed by industry expertise, we simplify complex fluid power standards.

1. What Is the Main Role of a Hydraulic Fitting?

Connecting Hoses and Components Securely

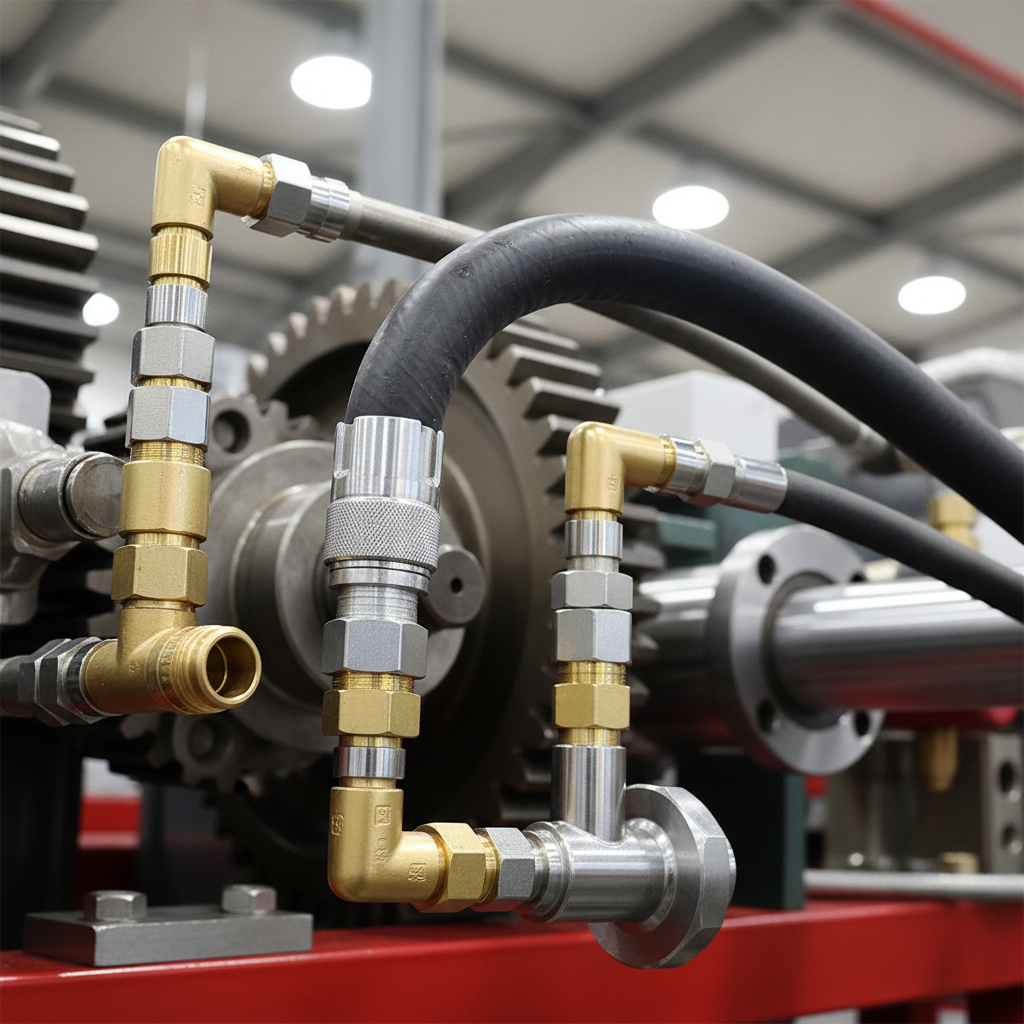

Hydraulic fittings serve as the fundamental bridge between various distinct parts of a fluid power system. Their primary job involves joining hoses to pumps, valves, cylinders, or other hoses without allowing disconnection under stress. A secure connection dictates whether your machinery operates smoothly or suffers from catastrophic separation events during operation. Every connection point represents a potential weak link if you fail choosing high-quality components matching your system specifications. Engineers design these parts specifically for withstanding immense physical forces while maintaining a rigid mechanical grip on the attached tube or hose end. Here’s the deal, failing to secure this link compromises your entire operation instantly. You need a full inventory of reliable options, so exploring our complete range of hydraulic fittings helps ensuring system compatibility.

Maintaining System Pressure Integrity

Pressure integrity remains the backbone of any hydraulic circuit’s efficiency and power transmission capability. A fitting must contain internal fluid pressure without expanding, cracking, or deforming under load. High-pressure spikes often occur during rapid valve closures or heavy lifting cycles, testing metal limits. If a component fails containing this energy, you lose force transmission immediately. Proper selection ensures that every connector handles maximum operating pressures plus a safety factor margin. We typically recommend using components rated higher than your system’s peak pressure. Doing so prevents fatigue failure over long service life cycles.

Ensuring Leak-Free Fluid Transmission

Leaks represent more than just messy cleanup jobs; they indicate wasted energy and environmental contamination risks. A hydraulic fitting must provide a perfect seal against fluid escape even when temperatures fluctuate wildly. Different sealing methods like metal-to-metal seals or elastomeric O-rings achieve this goal differently. Your choice depends heavily on fluid type and operating environment conditions. Preventing leaks saves money on oil replenishment while protecting sensitive ground areas from pollution. Effective transmission means every drop of fluid pumped contributes directly toward mechanical work rather than seeping out onto factory floors.

| Function | Application Needs | |

|---|---|---|

| Secure Connection | High vibration resistance, mechanical locking | |

| Pressure Integrity | Heavy-duty wall thickness, certified materials | |

| Fluid Sealing | Compatible elastomers, precise machining | |

| Flow Direction | Elbows, tees, crosses for routing | |

| Adaptability | Connecting metric to imperial threads |

Analysis: Secure connections form the foundation of safety in high-pressure environments. Without reliable integrity, efficiency drops significantly.

2. Why Is the Correct Hydraulic Fitting Size Crucial?

Preventing Leaks from Poor Connections

Incorrect sizing stands out as a leading cause for hydraulic leaks in industrial machinery today. Even a microscopic mismatch between thread pitches or diameters allows fluid escaping under high pressure. Leaks typically start slow but accelerate rapidly as pressurized fluid erodes metal surfaces. Using digital calipers helps verifying dimensions down to the millimeter before attempting installation. You might be wondering, does a small difference really matter? Yes, because high-pressure fluid finds every possible path of least resistance. Preventing these leaks requires absolute precision during component selection phases.

Measuring Inner and Outer Diameters

Sizing involves more than just guessing a fraction; you must measure both inner diameter (ID) and outer diameter (OD). The ID determines flow capacity while OD dictates thread compatibility and clearance. A restricted ID causes heat generation through fluid friction, damaging seals over time. Conversely, an oversized ID might result in loose connections lacking structural stability. You should use precise tools for measuring these dimensions accurately. Matching hose ID with fitting barb size ensures a tight interference fit necessary for crimping. Neglecting this step often results in hose blow-off accidents.

Matching Threads for a Perfect Fit

Thread geometry varies significantly across different standards like BSP, NPT, and Metric. Connecting a BSP male into an NPT female might seem possible initially but effectively ruins both threads. One standard uses parallel threads while another relies on tapered ones for sealing. Forcing mismatched threads destroys delicate ridges, preventing any chance of a proper seal. You must identify thread pitch using a gauge before assembly. A perfect fit creates a continuous metal path capable of sustaining heavy loads without stripping.

| Standard | Measurement Type | Common Use | |

|---|---|---|---|

| NPT | Inch (Tapered) | US General Industrial | |

| BSP | Inch (Parallel/Tapered) | UK, Europe, Asia | |

| Metric | Millimeter | Global Heavy Equipment | |

| JIC | Inch (37° Flare) | High Pressure US/Global | |

| ORFS | Inch (Flat Face) | Leak-critical Systems |

Analysis: Accurate sizing prevents catastrophic blowouts. A mismatched thread compromises structural holding power immediately.

3. Which Material Suits Your Hydraulic Fitting Best?

Brass for Corrosion Resistance

Brass fittings offer excellent resistance against rust and corrosion in low-pressure applications. You frequently see them used for water lines, pneumatic systems, or low-pressure hydraulics. Their softer nature makes them easy for machining and sealing against harder metals. However, brass lacks tensile strength needed for extremely high-pressure spikes found in heavy machinery. But here’s the kicker, brass deforms easily if over-tightened. We suggest limiting brass usage strictly toward appropriate pressure ranges. Checking our hydraulic fitting material standards provides deeper insight into alloy composition choices.

Steel for High-Pressure Durability

Carbon steel remains the industry workhorse for most hydraulic applications requiring high strength. Manufacturers typically plate carbon steel with zinc or zinc-nickel coatings preventing rust formation. This material handles extreme pressure cycles without fatiguing or stretching. Steel fittings serve ideally in construction equipment, agricultural machinery, and industrial presses. You get a balance of cost-effectiveness and rugged performance. Regular maintenance checks ensure coating integrity remains intact, preventing underlying corrosion.

Stainless Steel for Harsh Environments

Stainless steel offers superior protection when your equipment operates near saltwater or caustic chemicals. Grade 316 stainless steel resists pitting and rusting even under harsh marine conditions. While significantly more expensive than carbon steel, it pays off by lasting years longer in corrosive zones. You should select stainless steel for offshore oil rigs, food processing plants, or chemical handling units. High material hardness also allows higher pressure ratings compared strictly against brass. Investing in stainless prevents frequent replacement downtime costs.

| Material | Pressure Rating | Corrosion Resistance | Cost | |

|---|---|---|---|---|

| Brass | Low | High | Medium | |

| Carbon Steel | High | Low (needs plating) | Low | |

| Stainless Steel | Very High | Very High | High | |

| Aluminum | Low/Medium | Medium | Medium |

Analysis: Material selection dictates longevity. Choosing steel for strength and stainless for environment saves money long-term.

4. How Vital Is Pressure Rating for a Hydraulic Fitting?

Withstanding System Pressure Spikes

Hydraulic systems rarely operate at a constant, steady pressure level throughout a cycle. Activating a cylinder or hitting a hard stop creates massive pressure spikes instantly. These transient surges can exceed normal operating pressure by several times for milliseconds. A fitting must absorb this shock without bursting or losing its seal. Ready for the good part? Properly rated fittings usually include a 4:1 safety factor. This means a fitting rated for 3,000 PSI can theoretically burst only above 12,000 PSI. Reliance on this safety margin for regular operation acts dangerously, however.

Avoiding Catastrophic Component Failure

Failure at high pressure resembles an explosion, spraying hot oil everywhere. Metal fragments can become projectiles endangering anyone standing nearby. You simply cannot ignore pressure ratings when selecting replacement parts. A burst fitting halts production immediately, requiring expensive cleanup and repairs. Ensure every component meets or exceeds the maximum potential pressure your pump generates. Never assume a similar-looking part holds equivalent pressure handling capabilities.

Matching Fittings to Hose Ratings

Your assembly proves only as strong as its weakest individual link. If you connect a 5,000 PSI hose using a 3,000 PSI fitting, the entire assembly rates only at 3,000 PSI. Mismatched ratings create a false sense of security for operators. You must verify that both hose and termination ends carry compatible pressure certifications. Inspecting stamped markings on fittings reveals their rated capacity. Always downgrade the assembly rating toward the lowest component value.

| Fitting Type | Max Pressure (approx PSI) | Usage Context | |

|---|---|---|---|

| NPT | 1,000 – 4,000 | General Purpose | |

| JIC 37° | up to 5,000 | High Pressure | |

| ORFS | up to 6,000 | Vibration/High Pressure | |

| Code 61 Flange | 3,000 | Large Bore Lines | |

| Code 62 Flange | 6,000 | Heavy Duty |

Analysis: Pressure ratings preserve safety. Always matching components to the highest system spike prevents disasters.

5. What Are Common Hydraulic Fitting Connection Types?

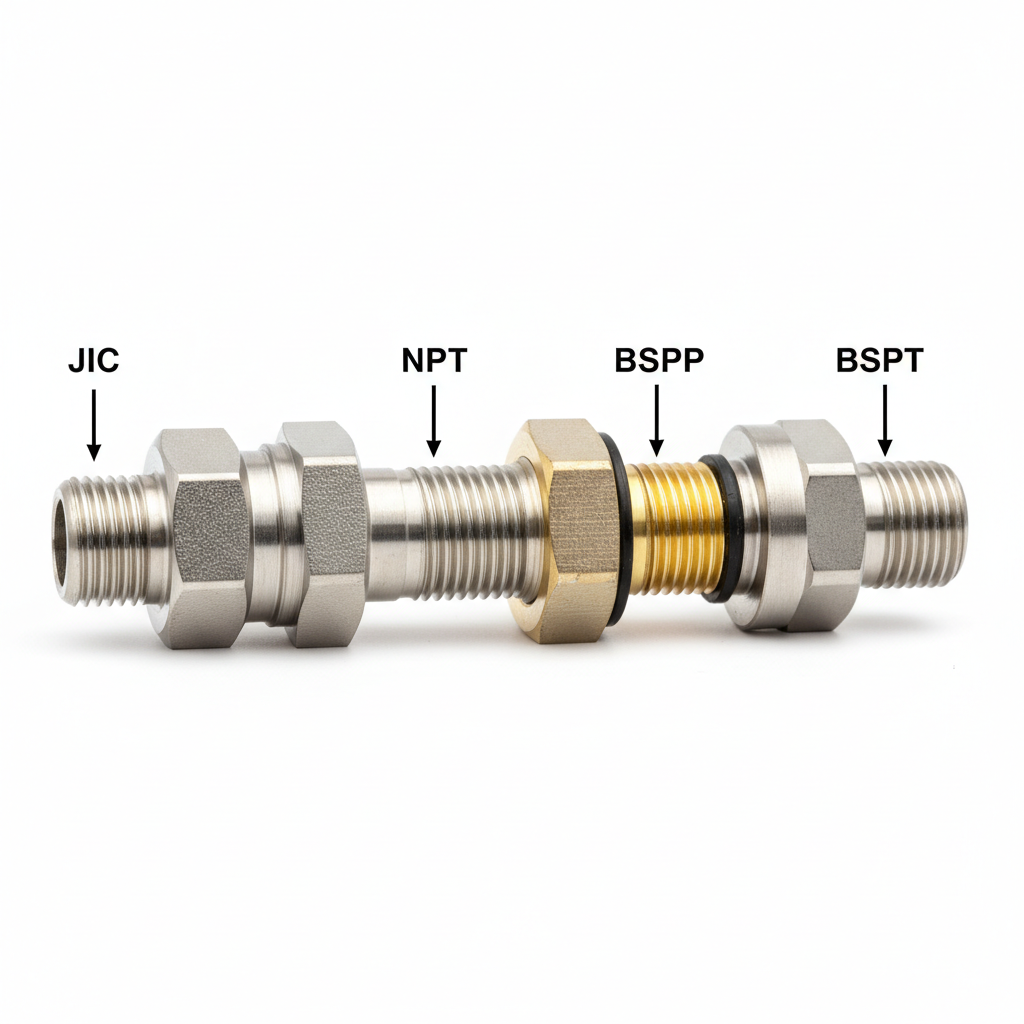

British Standard Pipe (BSP) Features

BSP fittings dominate the market across Europe, Asia, and Australia. They come in two main varieties: BSPP (Parallel) and BSPT (Tapered). BSPP relies on a bonded seal or O-ring for tightness, whereas BSPT seals through thread deformation. You must distinguish between them because they look similar but function differently. This is where it gets interesting, forcing a tapered male into a parallel female might hold temporarily but fails under load. Most modern global equipment utilizes BSP due to its widespread availability.

Metric L and S Series Explained

Metric fittings, particularly DIN standards, feature “Light” (L) and “Heavy” (S) series. Both use the same thread size but differ significantly in tube diameter and wall thickness capability. The Heavy series handles higher pressures and vibrations suited for construction machinery. You identify them by measuring the sealing cone size or tube seat. Mixing L and S series results in immediate leaks because sealing surfaces do not contact correctly. German and Chinese machinery frequently employs these robust metric standards.

Understanding Thread Pitches and Seals

Thread pitch refers simply to the distance between individual threads. Imperial threads count threads per inch, while metric threads measure distance in millimeters. A thread gauge becomes your best friend when identifying unknown fittings. Sealing mechanisms also vary from metal-to-metal cones toward soft O-ring seals. Soft seals generally provide better leak resistance in vibrating systems. You should prioritize understanding these nuances for accurate identification.

| Feature | BSP | NPT | Metric DIN | |

|---|---|---|---|---|

| Thread Form | Whitworth 55° | American 60° | Metric 60° | |

| Sealing | Cone/Bonded Seal | Thread Interference | Bite Ring/O-Ring | |

| Taper Available? | Yes (BSPT) | Yes (NPTF) | No (Parallel usually) | |

| Primary Region | UK/EU/Asia | USA | Germany/Global |

Analysis: Identifying connection types correctly ensures compatibility. Thread pitch and sealing style define the fitting’s identity.

6. Why Choose JIC Standards for a Hydraulic Fitting?

Industry Standard for Diagnostic Tests

JIC (Joint Industry Council) fittings utilize a 37-degree flare seating surface. This design became standard because it handles high pressure while remaining easy for assembly. You often find JIC fittings on diagnostic test points where technicians attach gauges. Their popularity stems from broad compatibility across different brands and regions. A simple wrench tightens the metal-to-metal seal effectively. What’s the real story? They gained fame in the US but now serve global markets reliably.

Reliable Performance Under High Pressure

The 37-degree flare creates a large metal sealing area. When you tighten the nut, it presses the flared tube against the fitting nose, forming a seal capable of holding 5,000 PSI or more. This metal-to-metal contact resists breakdown from hydraulic fluid chemicals or heat. Unlike O-rings that might crack over time, metal seats remain robust. You can trust JIC connections on main power lines where durability counts most.

Easy Maintenance and Reusability

One massive advantage involves reusability. You can disconnect and reconnect a JIC fitting multiple times without destroying the seal. This feature proves invaluable during maintenance or component replacement. Other types, like compression fittings, often require replacing the ferrule after disconnection. JIC fittings allow technicians to service equipment quickly in the field. Simply inspecting the flare for scratches ensures continued performance.

| Spec | JIC 37° Flare | SAE 45° Flare | |

|---|---|---|---|

| Angle | 37 Degrees | 45 Degrees | |

| Application | High Pressure Hydraulic | Low Pressure/Refrigeration | |

| Material | Steel/Stainless | Brass (mostly) | |

| Thread | UN/UNF | UN/UNF | |

| Interchangeable? | No | No |

Analysis: JIC offers versatility and durability. Its reusable nature makes it a favorite for maintenance-heavy systems.

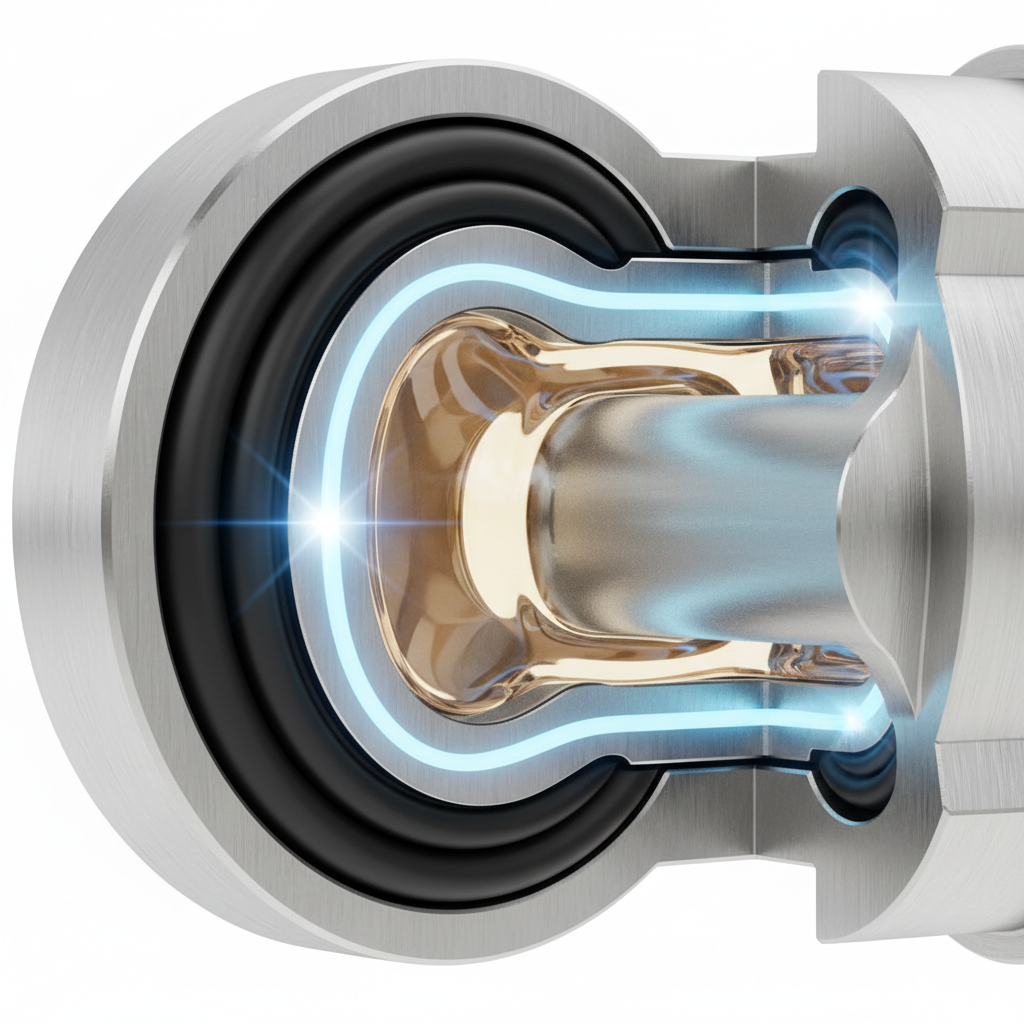

7. When Is an O-Ring Seal Best for a Hydraulic Fitting?

Creating a Leak-Proof Flat Face Seal

O-Ring Face Seal (ORFS) fittings represent the gold standard for leak prevention. Instead of deforming metal threads, they compress a rubber O-ring against a flat metal face. This design eliminates leak paths virtually completely. You should choose ORFS for applications where zero leakage is mandatory. Wait, there’s more. The seal actually improves as pressure increases, pushing the O-ring tighter against the groove wall. This dynamic sealing action surpasses traditional metal flares.

Reducing Torqueing Risks Significantly

Traditional fittings require high torque for deforming metal into a seal, risking cracks. ORFS fittings seal upon contact and compression, requiring less rotation to achieve tightness. This reduces physical stress placed on the fitting body and threads. You avoid the common problem of over-torqueing that shears off threads. Installation feels smoother and provides tactile feedback when the face meets the seat. This design protects your expensive components from installation damage.

Ideal Applications for ORFS Fittings

High-vibration environments wreak havoc on standard metal seals. Construction excavators and mining trucks vibrate constantly, loosening JIC or NPT connections. The elasticity of an O-ring absorbs this vibration without breaking contact. You find ORFS fittings extensively in modern off-highway equipment. They withstand pressure pulses that typically fatigue other connection types. Using them reduces long-term maintenance needs drastically.

| Seal Type | Leak Resistance | Vibration Handling | Torque Required | |

|---|---|---|---|---|

| ORFS | Excellent | Excellent | Medium | |

| JIC Flare | Good | Moderate | High | |

| NPT Taper | Fair | Poor | High | |

| BSP Bonded | Very Good | Good | Medium |

Analysis: ORFS handles vibration best. The elastomeric seal forgives movement that loosens metal contacts.

8. How Do You Install a Hydraulic Fitting Correctly?

Following Strict Assembly Procedures

Installation requires more discipline than simply cranking a wrench until it stops moving. You must clean all threads and mating surfaces meticulously before assembly. Dirt particles compromise seals instantly, leading toward leaks later. Lubricating the O-ring or threads ensures smooth movement and accurate torque readings. Ignoring these preparation steps practically guarantees failure. Don’t get me wrong, speed matters, but haste causes rework. Following a checklist prevents skipping vital cleaning steps.

Ensuring a Solid Mechanical Connection

Alignment plays a massive role during installation. You must align the hose end perfectly straight with the fitting fitting. Forcing a connection at an angle crosses threads and prevents proper seating. Hand-tighten the nut first ensuring smooth engagement before using tools. This tactile check confirms that threads mesh correctly. Once hand-tight, use a wrench for final tightening. A solid mechanical connection feels rigid and secure without wobbling.

Avoiding Over-Tightening and Damage

Most people assume tighter means better, but that logic fails here. Over-tightening stretches threads, cracks flares, and crushes O-rings beyond recovery. You should use the “flats from wrench resistance” (FFWR) method or a torque wrench. FFWR involves turning the nut a specific number of hex flats after feeling resistance. This provides a consistent clamping force. Stopping at the right moment preserves the fitting for future use.

| Thread Size | Rec. Torque (ft-lbs) | Flats Method (Turn) | |

|---|---|---|---|

| 1/4″ | 10 – 12 | 1.5 – 2 Flats | |

| 3/8″ | 18 – 20 | 1.5 – 2 Flats | |

| 1/2″ | 32 – 40 | 1.5 – 2 Flats | |

| 3/4″ | 65 – 80 | 1 – 1.5 Flats | |

| 1″ | 90 – 110 | 0.5 – 1 Flat |

Analysis: Installation technique determines success. Proper torque and alignment prevent damage that leads to leaks.

9. What Signs Indicate a Faulty Hydraulic Fitting?

Identifying Visible Leaks and Wear

The most obvious sign involves hydraulic fluid dripping or pooling underneath a connection point. Wetness around a nut suggests seal failure or loosening. You should also look for corrosion eating away metal surfaces. Rust weakens the body, making it susceptible to bursting. Here is the bottom line, if it looks wet, it needs attention. Inspect hoses near the crimp for cracks or cover abrasion. Catching these visual cues early prevents massive oil spills.

Monitoring for Pressure Drops

A slow leak might not create a puddle immediately but reduces system efficiency. You might notice cylinders moving slower or pumps working harder to maintain pressure. Gauges showing lower-than-normal readings often point toward a leak somewhere. Fluid escaping means energy leaving the system unused. Troubleshooting involves isolating circuits for finding the pressure loss source. Addressing this restores machine performance and fuel efficiency.

Preventing Safety Hazards for Operators

A faulty fitting poses a direct threat through high-pressure injection injuries. A fine stream of oil under pressure cuts skin like a knife, injecting toxic fluid. You must treat every potential leak with extreme caution. Never use your hand for checking leaks while the system runs. Replacing worn components proactively protects personnel from life-altering injuries. Consult our hydraulic fitting maintenance guides for safety protocols.

| Symptom | Probable Cause | Action Required | |

|---|---|---|---|

| Wetness on nut | Loose nut / Worn seal | Tighten / Replace O-ring | |

| Cracked body | Over-torque / Fatigue | Replace immediately | |

| Rusting | Environmental mismatch | Switch to Stainless | |

| Stripped thread | Forced assembly | Replace fitting & adapter | |

| Hose popping off | Incorrect crimp spec | Replace hose assembly |

Analysis: Vigilance prevents accidents. Recognizing wear signs early allows planned maintenance rather than emergency repairs.

10. Where Can You Buy Quality Hydraulic Fittings?

Selecting a Reputable Industry Supplier

Buying fittings from unknown sources risks receiving sub-par materials with dangerous flaws. You need a supplier who controls their manufacturing process strictly. A reputable vendor provides traceability for materials and rigorous testing data. They understand the difference between industrial grade and hobbyist parts. Partnering with established companies ensures consistency across batches. Let’s face it, cheap parts cost more when they fail. Choose reliability over the lowest initial price tag.

Verifying Quality Standards and Certs

Quality suppliers proudly display their ISO certifications and material reports. You should ask for documentation proving adherence to SAE, DIN, or ISO standards. This paperwork guarantees that the steel alloy meets strength requirements. Without certification, you essentially gamble on safety. We provide full transparency regarding our manufacturing standards. Verification builds trust and ensures regulatory compliance for your machinery.

Contacting Experts for Custom Solutions

Sometimes off-the-shelf parts fail to meet unique system constraints. You might need a custom bend angle or a specialized thread combination. Expert manufacturers offer engineering support for designing bespoke solutions. We can produce fittings tailored exactly for your specific machinery needs. Getting a custom hydraulic fittings quote starts the process of optimizing your system. Professional support turns complex problems into engineered solutions.

| Criteria | Good Supplier | Bad Supplier | |

|---|---|---|---|

| Certifications | ISO 9001, SAE, DIN | None / Vague | |

| Material Info | Specific Alloys (e.g. 316L) | “Metal” / Generic | |

| Testing | Pressure / Salt Spray | None | |

| Support | Engineering Team | Sales Only | |

| Stock | Extensive Inventory | Limited / Dropship |

Analysis: Sourcing matters. A trusted supplier provides certified safety, while unknown vendors offer only risk.

Conclusion

We covered the vital aspects of selecting hydraulic fittings, including sizing, pressure ratings, material choices, and the distinct benefits of JIC versus ORFS types. Making the right choice protects your expensive equipment and, more importantly, your personnel from harm. Don’t risk catastrophic failure by guessing; browse our extensive catalog or contact Topa Hydraulic today for expert selection advice.

FAQ

Q1: What is the best hydraulic fitting material? The best material depends on your application. Steel offers high strength for heavy machinery, stainless steel provides superior corrosion resistance for marine environments, and brass works well for low-pressure water or pneumatic systems.

Q2: How do I measure a hydraulic fitting thread? You measure a thread using a caliper for the outer diameter and a thread pitch gauge for the distance between threads. Compare these measurements against a standard thread chart to identify if it is NPT, BSP, or Metric.

Q3: Can I reuse a hydraulic fitting? Yes, but with caution. JIC and other metal-to-metal fittings are generally reusable if the seating surface remains undamaged. However, fittings relying on crushed ferrules or deformed threads typically require replacement after disassembly.

Q4: What causes hydraulic fitting failure? Common causes include improper installation torque (over or under-tightening), mismatched threads, material fatigue from pressure spikes, and corrosion. Vibration also frequently loosens connections, leading to leaks and eventual failure.

Q5: Are JIC and NPT fittings interchangeable? No, they are not. JIC uses a 37-degree flare sealing surface with parallel threads, while NPT uses tapered threads that seal by deformation. Attempting to connect them directly will damage threads and cause leaks.